Advanced White Wine Making

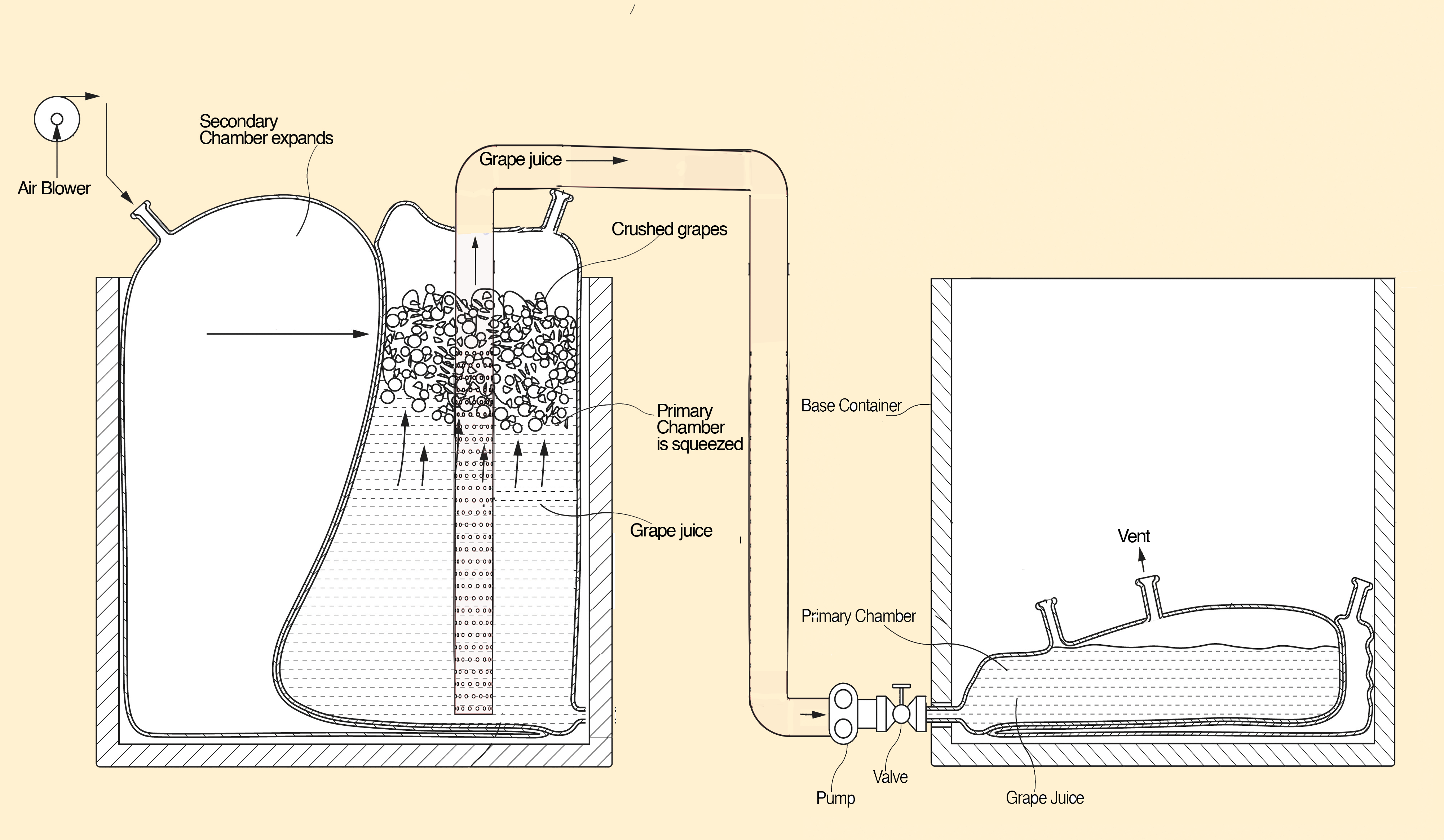

Wine Fermentor + Press

Quality wine with no oxidation

Yield is 150 gallons/ton or more

Built-in press

No cleaning

The GOfermentor has many advantages when making white wine. Such as minimal air contact, no cleaning, low capital cost, and minimal water usage. The GOfermentor integral press mechanism can be used to press out the juice from the grape must. This feature eliminates the need for a press, and is a convenient way of performing what is typically a very messy operation. The operation is gentle, and oxidation is minimal, since air contact is minimized. The GOfermentor provides temperature control, bâtonnage and sampling.

Pomace after the juice is pressed

Press out the juice into a second GOliner

Once the primary chamber has been filled to the desired amount (range 200lb to 1 ton of crushed grapes), the destemmer crusher is disconnected. The Press Tube in inserted into the vent port and the fill port is capped shut. A wine pump is connected to the Press Tube and the pump discharge is connected to the inlet of a second GOfermentor/GOliner. Fermentation of the juice will be done in this second GOliner. A GOfermentor controller is attached to first GOliner and the inflation hose connected to the inflation bag of the first GOliner. The PRESS function is activated to press out all the juice into the second GOliner. The first GOliner containing the residual skins and seeds is removed and discarded. No scooping out sugary grape pulp! No cleaning of a crush tank or press! And, this entire operation is conducted with minimal air contact retaining aromatics and enabling the production of low sulfite wines.

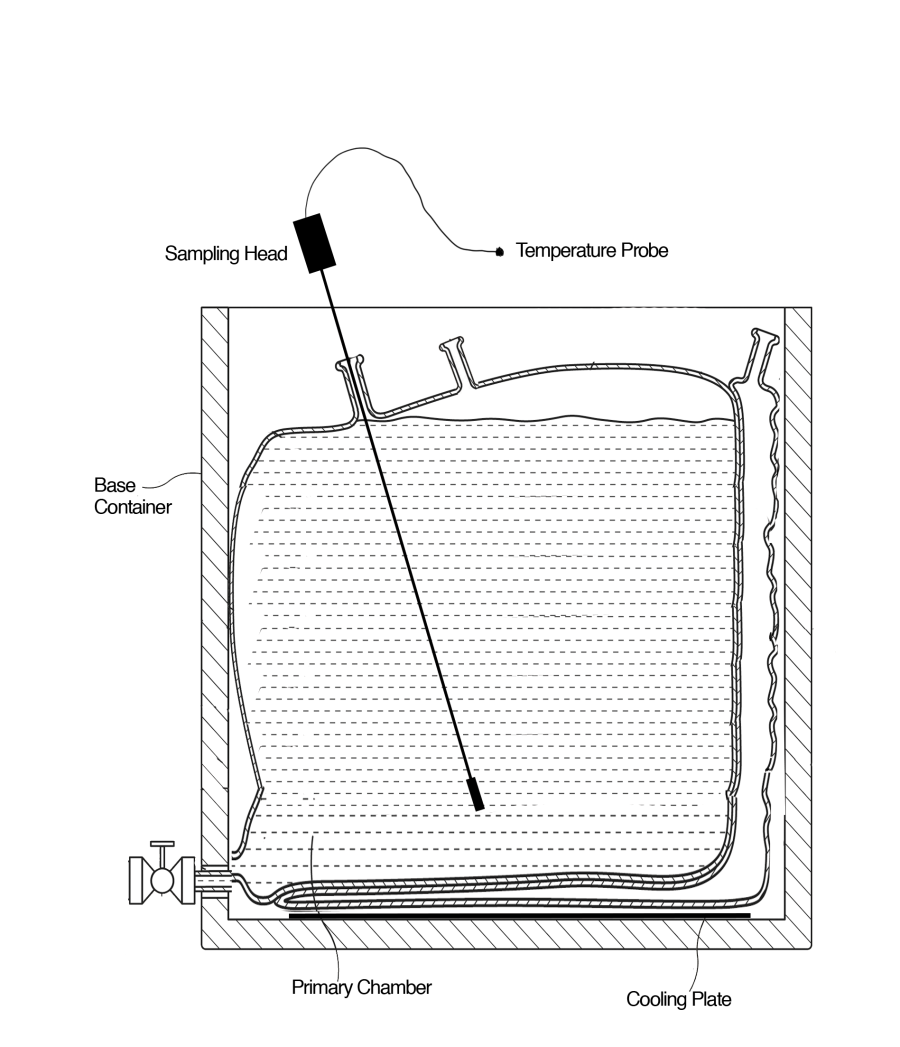

Temperature control

White wine generally requires lower temperatures and the optional GOcooler heat exchanger plate in the GOfermentor is an efficient way of controlling temperature. A temperature probe inside the sampling tube provides the temperature of the must and it can automatically control coolant flow through the optional GOcooler to maintain a set temperature.

Fermentation

Fermentation is performed in the GOfermentor. Use of the single-use GOliner ensures a clean wine. The sealed bag keeps air and flies out. This can minimize, or even eliminate the need for sulfite additions, resulting in better flavors. The closed design condenses aromatic and volatile components back into the liquid retaining fruity and fresh characteristics. Micro oxygenation can be performed if desired by sparging air through the sample line.

Bâtonnage

While "punchdown" is not required in white wine production as there is no cap, the mechanism is still useful for stirring up settled lees (bâtonage) adding to the smoothness and body of the white wine. The sampling diptube makes taking samples during fermentation easy without introducing any oxygen. After fermentation is complete, the GOfermentor contents are simply pumped (racked) to a SmartBarrel liner, barrels, or other white wine racking/aging equipment.