SmartBarrel

Upgrade your Variable Capacity Tank to a SmartBarrel®

"VT tanks have poor seals promote oxidation and microbial spoilage, VTs have long been considered a necessary evil for small lot storage. Everybody hates them! SmartBarrel liners, which eliminate these problems, are a boon to small producer wine quality, to say nothing of their convenience, economy and the elimination of water and chemicals for cleaning." Notes Clark Smith.

Storing wine safely has been a problem for centuries. Oxygen and microbial contamination can quickly ruin wine. Many solutions have been attempted - from sealed amphora to rubber bladders. Modern wine storage practice utilizes mainly barrels, metal tanks and Variable Capacity Tanks. All these devices have a critical weakness - they are rigid containers with a poor seal. Wine loss due to leakage, evaporation, and removal causes air to enter the container creating spoilage. Some techniques for the "floating head" tanks, argon blanketing are used, but these are expensive and prone to failure.

"There's no water usage, no washing involved, and no wastewater generation. The liners are available instantly, whenever they're needed, with absolute cleanliness assured. We go from one liner to another until the bottling line, handling everything in disposable containers." notes Dr Vijay Singh, the inventor of the system.

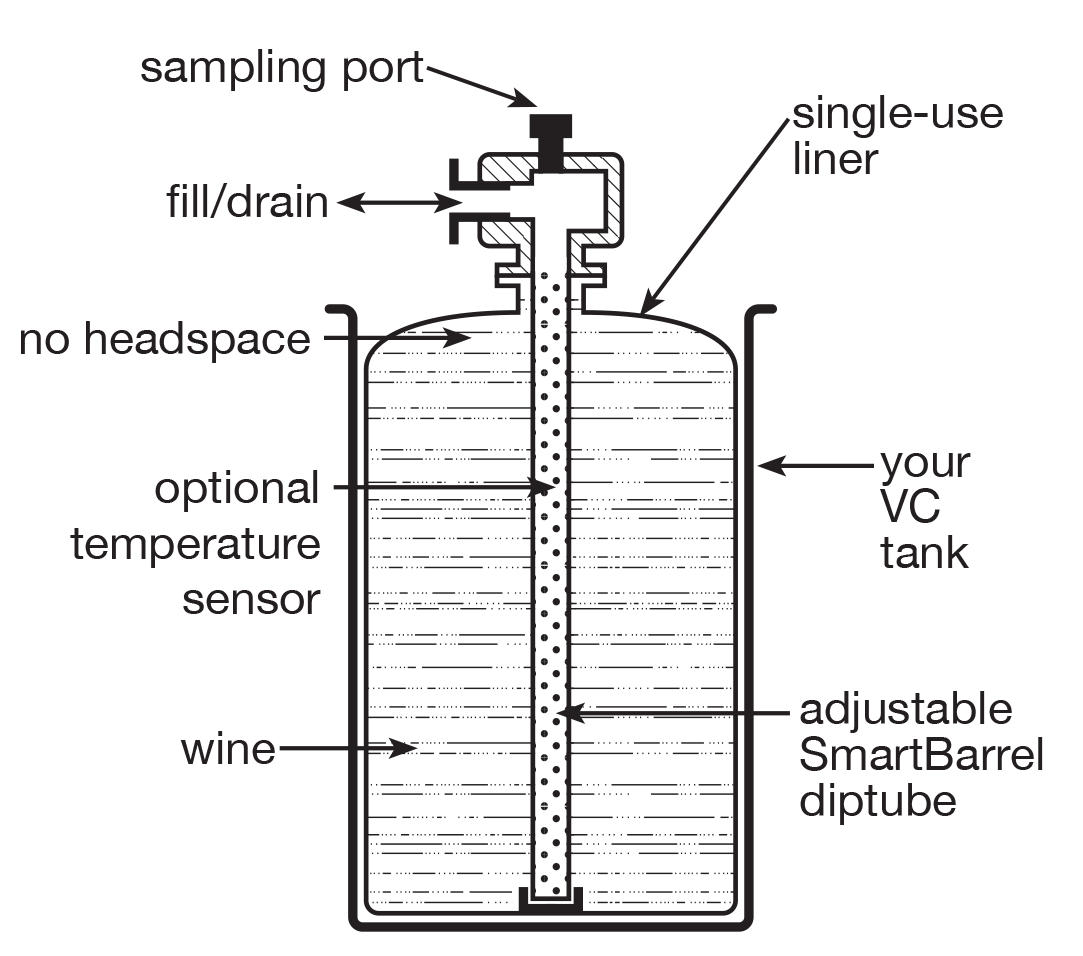

Upgrading your Variable Capacity tank to a SmartBarrel provides an effective, economical, and reliable solution for the safe storage of wine during racking, aging, and bulk. This technology was developed over years of experimentation based on Dr Vijay Singh's unsurpassed knowledge of flexible pharmaceutical processing. The key component of the SmartBarrel is the patented diptube. The wine is stored in single-use liners that have extremely low oxygen permeability. The contact materials have been used for bag-in-box systems for years and are known not to impart odors or other negative effects.

All operations with the SmartBarrel are done with wine pumps. The diptube is connected to the liner using a standard 2" triclamp. Wine is pumped into the liner through the fill/drain port on the diptube. Wine is pumped out of the fill/drain port. As wine is removed, the liner collapses so no headspace is created. The perforated design of the diptube ensures that the clean wine is drawn out first. No "topping off" is ever needed. Sampling using a traditional wine thief introduces air and can cause cross-contamination. The SmartBarrel does not use a wine thief. Samples are taken using a vacuum aspirator that assures that nothing is introduced into the wine during sampling.

Traditional cellar operations, such as "oaking" are easily performed by introducing inexpensive and environmentally sustainable oak products - chips, staves, or cubes into the SmartBarrel liners. A side -benefit of this procedure is that when the appropriate level of "oaking" is achieved the process can be easily terminated by simply pumping the wine out to a new liner without oak products. The chips, staves, etc are retained in the original liner by the perforations in the diptube. This is not possible with traditional wood barrels.

Liners are single-use, so there is no cleaning. A perfectly clean storage container is instantly available.

"Once you've got good wine it has to be kept safe. Our system protects the end product. You can't afford to ruin it due to poor storage." Says Vijay Singh the inventor of the SmartBarrel System.

Download SmartBarrel VC tank Setup