Stop taking chances with your wine

SmartBarrel®patented zero headspace storage system

SmartBarrel®patented zero headspace storage system

Keep your wine safe

WINE STORAGE SYSTEM FOR 60 GALLON AND 330 GALLON TANKS

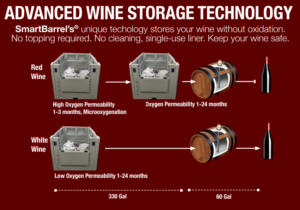

The SmartBarrel provides an effective, economical, and reliable solution for the safe storage of wine during racking, aging, and bulk storage. This technology was developed over years of experimentation based on Dr. Singh's unsurpassed knowledge of flexible pharmaceutical processing. The key component of the SmartBarrel is the patented diptube. The wine is stored in single-use liners that have extremely low oxygen permeability. The contact materials have been used for bag-in-box systems for years and are known not to impart odors or other negative effects.

All operations with the SmartBarrel are done with wine pumps. The diptube is connected to the liner using a standard 2" triclamp. Wine is pumped into the liner through the fill/drain port on the diptube. Wine is removed by pumping out of the fill/drain port. As wine is removed, the liner collapses so headspace is never created. No topping off is ever needed. The perforated design of the diptube ensures that the clean wine is automatically drawn out first. Sampling using a traditional wine thief introduces air and can cause cross-contamination. The SmartBarrel does not use a wine thief. Samples are taken using a vacuum aspirator that assures that nothing is introduced into the wine during sampling.

Losing track of your wines?

Try the Smart Solution: SmartBarrel

The SmartBarrel has been keeping your wines safe from oxidation, Brettanomyces, and other contamination for years. Our single-use pharma clean liners eliminate washing. The patented diptube eliminates the need for "topping-off". Wine is protected from oxidation, even at low volumes. Hundreds of SmartBarrel systems are in use worldwide.

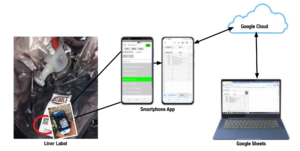

"Now SmartBarrel just got smarter!" notes Vijay Singh, inventor of the SmartBarrel System. "Not only keep your wine safe, but know what's in each container, the grapes used, when it was last racked. Just use your smartphone to scan the QR code on the liner. You can view and edit the data from anywhere you have internet. Your colleagues can update the information in real-time using a phone, tablet, or PC. Imagine - no more out-of-date Post It notes!"

The new SmartBarrel tracking system gives you easy access to all your wine storage information. Best of all the service is free with purchase of SmartBarrel single-use liners.

Here is how the magic works:

1. Store your information in Google sheets: Each batch is assigned a user-generated unique name. Create a Google Sheets spreadsheet. Enter information into the spreadsheet. For example - date made, varietal, status, volume, assay data, tasting notes, aging log, and so on. GOfermentor supplies a template that you can copy or modify for your needs.

2. Link the QR code on the liner to the batch: When you fill a SmartBarrel liner use the SmartBarrel App to link the liner QR code to the batch name. When you empty it, just unlink the QR code.

3. Scan the QR code with your phone: The SmartBarrel app connects you to the linked batch name and opens its Google Sheet for you to view and edit.

This simple and accessable tracking system allows you to bring your entire cellar under control. You can now know exactly what you have, how much of it, where it is, and its entire history. You can view everything on your phone or on your laptop. So can your authorized coworkers.

Uses your own Google cloud storage for security: GOfermentor provides a Google Sheets template for you to copy to create a Google sheet for each batch. Using your own Google account gives you full control and access to your information. GOfermentor cannot access your data.

QR codes on all liners: All SmartBarrel liners manufactured after June 2023 are already equipped with QR codes. For retrofit, you can purchase QR stickers to place on your older liners.

SmartBarrel App: Download the app from our website (currently only for Android - iOS coming soon). Free of charge.

The SmartBarrel provides an effective, economical, and reliable solution for the safe storage of wine during racking, aging, and bulk. This technology was developed over years of experimentation based on Dr. Singh's unsurpassed knowledge of flexible pharmaceutical processing. The key component of the SmartBarrel is the patented diptube. The wine is stored in single-use liners that have extremely low oxygen permeability. The contact materials have been used for bag-in-box systems for years and are known not to impart odors or other negative effects.

All operations with the SmartBarrel are done with wine pumps. The diptube is connected to the liner using a standard 2" triclamp. Wine is pumped into the liner through the fill/drain port on the diptube. As wine is removed, the liner collapses so headspace is never created. The patented design of the diptube ensures that the clean wine is drawn out first. No topping off is ever needed. Sampling using a traditional wine thief introduces air and can cause cross-contamination. The SmartBarrel does not use a wine thief. Samples are taken using a vacuum aspirator that assures that nothing is introduced into the wine during sampling.

Since the SmartBarrel liner has no headspace, partial volumes can be stored for up to 24 months. This is a boon to small wineries. You can start with say 50 gallons in a 60 gallon liner and dispense out wine when needed until the liner is empty.

Traditional cellar operations, such as oaking are easily performed by introducing inexpensive and environmentally sustainable oak products - chips, staves, or cubes into the SmartBarrel liners. A side -benefit of this procedure is that when the appropriate level of oaking is achieved the process can be easily terminated by simply pumping the wine out to a new liner without oak products. The chips, staves, etc. are retained in the original liner by the perforations in the diptube. This is not possible with traditional wood barrels.

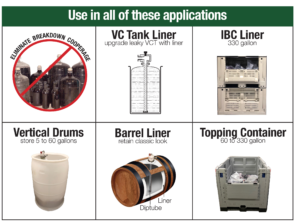

SmartBarrel liners are available in 60 gallon vertical and horizontal drum formats. Any user-supplied drum/barrel can be used to hold the liner. GOfermentor even offers kits to convert old wood barrels to SmartBarrels. 330 gallon liners are provided for use in user-supplied IBC/macrobins. Liners are single-use, so there is no cleaning. A perfectly clean storage container is instantly available.

For the SmartBarrel system you need:

-

- One reusable SmartBarrel diptube for each storage container.

-

- One cordless SmartBarrel aspirator/sampler for your entire facility.

-

- Single-use SmartBarrel liners.

TO FILL - connect pump to fill with wine.

TO EMPTY - connect pump and suck wine out.

YOU CANNOT SIPHON THE WINE OUT SINCE THERE IS A VACUUM IN THE BAG.

REMEMBER THERE IS NO HEADSPACE.

An entire wine racking system can be built using the SmartBarrel concept. No tanks are needed and no cleaning is necessary. By not using wood barrels you can minimize brett contamination and also reduce sulfite additions. Wine can be pressed right into IBC SmartBarrels each with a capacity of 300 gallons. These can be moved around, shipped, and stacked. Racking is done by transferring to new liners. Oaking can be done by the addition of various clean oak products. ML fermentation can be performed in the liners. Liners with varying oxygen permeability make controlled microxygenation safe and predictable. Low permeability liners can be used to store wine for years.

Differences Between the various SmartBarrel Kits:

There are 4 types of SmartBarrel Kits. The difference between them is only the length of the perforated stainless-steel tube. The most common is the short dip tube (SB-60M). This is used for 60 gallon vertical drum. It is identical, and interchangeable with SB-330IBC which is used for 330 gallon IBCs and totes. It can also be used for cylindrical open tanks up to 330 gallons. Long dip tube (SB-60W) is supplied as part of the wood barrel retrofit kit. It is longer because it must rest on the bottom of the horizontal wood barrel and protrude out of the cut opening. Finally, SB-330VCT is a variable length dip tube so it can be used in tall open top tanks. The dip tube can be extended to the height of the tank. It is used to convert Variable Capacity (VC tanks) to use liners.

Options:

The only option is the selection of the fill/empty fitting. There are 4 choices:

-TC20 2" Triclamp

-TC15 1 ½" Triclamp

- HFC Colder HFC12 quick-connect with auto shut-off*.

- NC no connector. User must connect to ¾" NPT female socket on SB dip tube head.

*Mating connectors are available from USPlastics

Ordering:

Select type of SB kit needed based on table below. Then add suffix for fitting. For example:

SB-60M-TC20 is SmartBarrel kit for 60 gallon vertical tank with 2" triclamp fitting

SB-330IBC-HFC is SmartBarrel kit for 330 gallon IBC with HFC12 quick connect fitting

Selection:

| Container Type | SB Kit needed | Features | Notes |

| 60gallon vertical drum | SB-60M-xxx vertical drum. | Short dip tube | Same as SB-60M |

| 330gallon IBC, tote, macrobin, or short open tank | SB-330IBC-xxx | Short dip tube | Same as SB-330IBC |

| 60gallon wood barrel | SB-60W-xxx | Long dip tube with barrel mounting kit | |

| VCT up to 1200 liters | SB-330VCT-xxx | Adjustable length (40")

Dip tube |

Check tank dimensions with us |

Download SmartBarrel Quick Start Guide